HESTASG

Detailed description

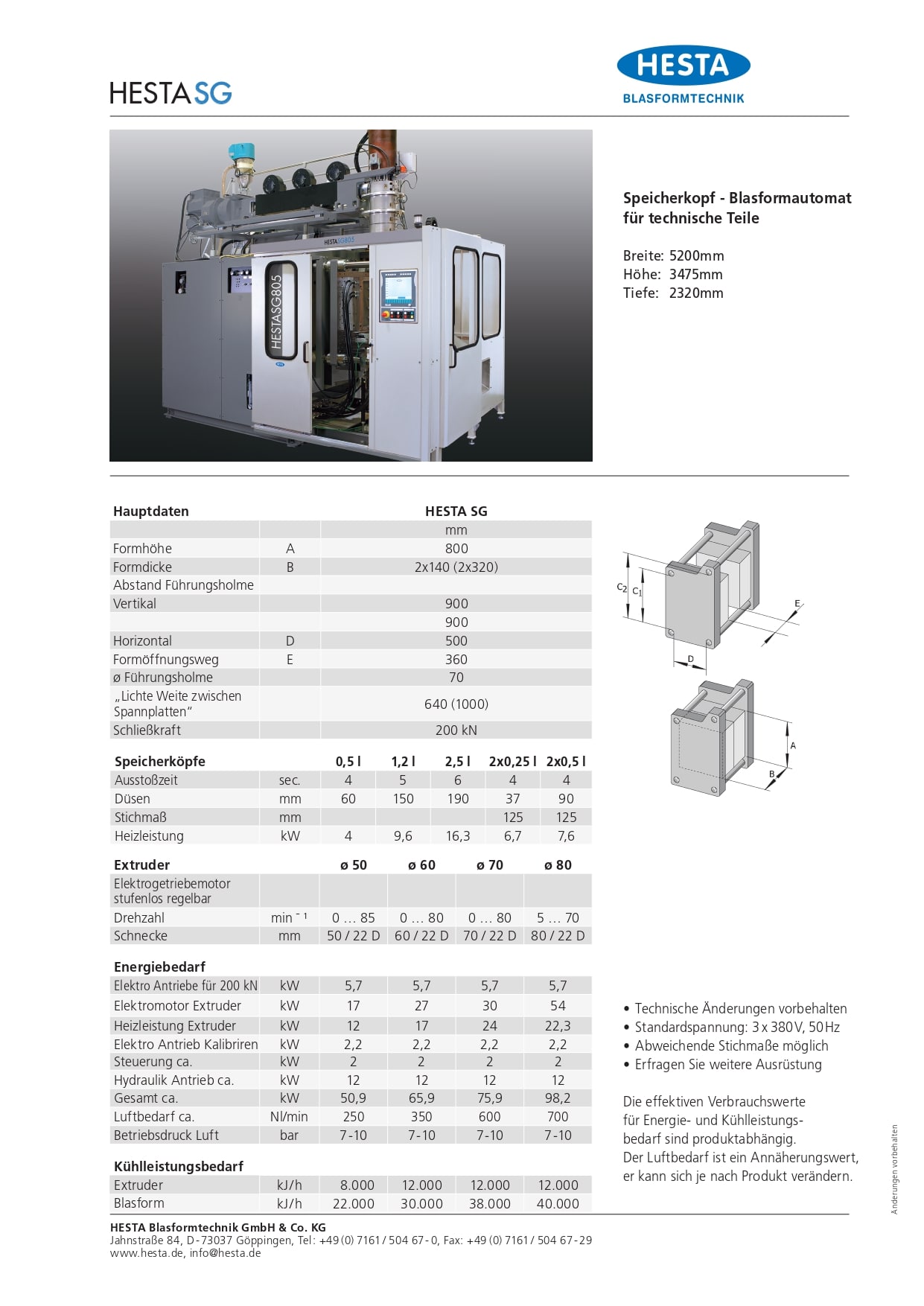

Our storage head machine is as versatile as it is usable, you can realize almost anything on this machine, starting with conventional storage head production, blowing from below for large-volume technical articles, needle blowing, suction blowing or 3D blowing. This all-electric machine not only impresses with its variable applicability, but also shines with its small footprint and perfect energy efficiency. With its optional or integrated hydraulic unit, various hydraulic form slides can of course also be connected and precisely controlled by our unique control system. Various sizes of storage heads and post-processing equipment are also available here.

The advantages for you:

- High article quality thanks to new HESTA storage heads

- Energy-saving, high-performance extruder with extruder drive that is unique in the world

- Long service life with precise mold guidance Closing force application without bending stress on the guide rails

- Variable transfer options to downstream stations using pneumatic grippers or handling robots

- Convenient machine operation

- Low space requirement due to very compact, open design with good accessibility

- Favourable price-performance ratio with high-quality new RESTA quality standard

To heat up for everything: Our universal extruder

The universal extruder is equipped with interchangeable feed bushes and allows the use of all blowable materials, in powder or granulate form, with or without the addition of reclaim. Depending on the material, appropriate screws, with or without mixing section, are used. The unique extruder drive is not only energy-saving but is also driven by four individual motors. This makes it easy to replace a single motor and also enables emergency operation or operation with reduced output while a single motor is being repaired.

Our wall thickness control:

An electronic wall thickness control or a PWDS system can easily be fitted to this machine.

Our memory head:

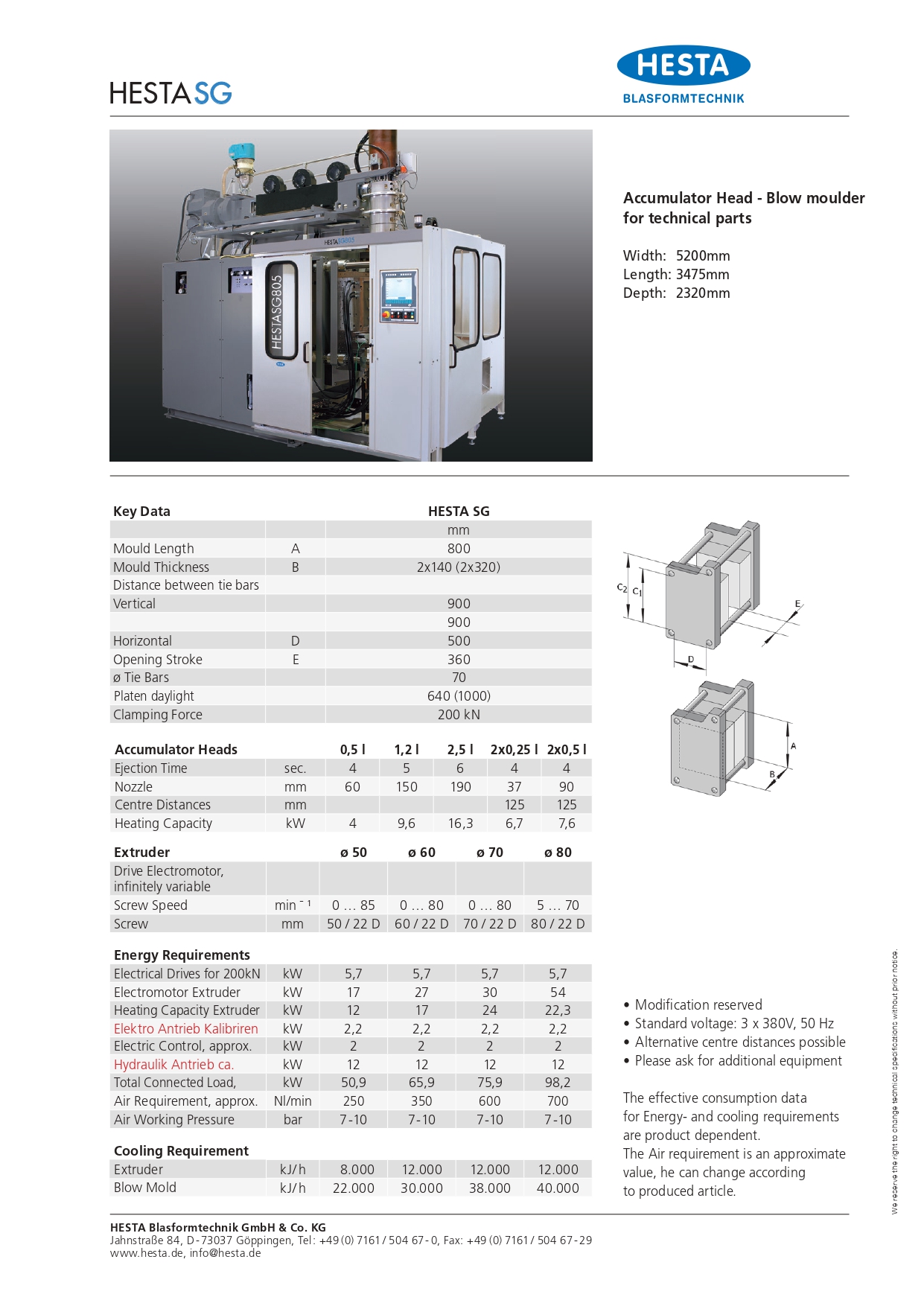

A finely graduated selection of accumulator heads is available, in single or multiple versions, mono or multi-layer versions for all common nozzle spacings.

The locking system

The open clamping system with four tie bars has an infinitely adjustable clamping force of up to 250 kN and is also driven by a maintenance-free crank drive, as well as adjustable mold opening travel. The tie bars are not subject to any bending stress and therefore ensure precise guidance of the clamping plates. The patented clamping cushion enables you to calibrate the mold thickness of +- 5 mm fully automatically, and the clamping force can also be optimally adjusted to your article in set-up mode. Human error settings are excluded with new HESTA. If the machine detects a minimal deviation during production, it immediately carries out an automatic set-up and adjusts the clamping force.

Drive for saving: electric drives and pneumatics

Energy-saving servo drives supply the extrusion and clamping unit. The associated servo drives from Beckhoff are always of the latest generation and enable economical production by optimally adapting the energy consumption to the utilization of the machine. The pneumatics control the blowing, cooling and transport functions. Punching and ejection with proven, sophisticated elements. The standard pneumatic valves are arranged on a central base plate for easy servicing.

Control cabinet & control:

The electrical control cabinet is vibration-damped, easily accessible and service-friendly when mounted on the machine. The programmable logic controller with front panel meets the highest demands for reproducibility, is simple, safe and clearly arranged. It allows individual input of all set values for the movement sequence, heating and wall thickness regulation. An internal background memory facilitates setpoint optimization. All entries and error messages are displayed in plain text. The warning and monitoring systems included in the basic version control the entire machine process. In the basic version, four authorization levels protect against unauthorized entries; personalized login can also be activated as an option. Inputs and all fault messages are recorded to track processes. Two monitor sizes are available for easy operation, depending on the machine type. The color 12 and 21 inch touch panels are directly connected to the Windows-based modular control system. Any number of setpoint records can be stored on an internal memory or conveniently on an external memory via a USB socket. This shortens changeover times, especially for small batch sizes, and increases efficiency. All common languages can be switched quickly and easily. Preparation for online service is a matter of course for us and is easily possible using pre-installed software.

Get in touch

Do you have any questions?

new HESTA blow moulding solutions GmbH & Co. KG

Address

Werrenwiesenstraße 89

D-73525 Schwäbisch Gmünd

info@hesta.de

support@hesta.de

Telephone & Fax

Phone +49 (0) 71 71 / 99 790 – 0

Fax +49 (0) 71 71 / 99 790 – 13

Daniel Knabel

Managing Director, Technical Director, Key Account

Phone +49 (0) 71 71 / 99 790 – 10

knabel[at]hesta.de