Enterprise

HESTA presented

We are here for you

Our promise: Where new HESTA is written on the label, it always contains uncompromising quality and excellent technology. With Swabian love for precision and German engineering , we ensure that your system always comes out exactly what you have defined with us. From the smallest bottle to the largest container. Promised!

The core competence of new HESTA is the development, production, commissioning and service of innovative solutions in the field of extrusion blow molding technology and machine-related automation. With 25 employees and a large team of partners and specialists, we are one of the leading providers on the market today.

new HESTA can look back on a long tradition, as the company was founded in 1948 as "Hermann Staehle Apparatebau – HESTA" was founded in Stuttgart and has always worked continuously on new innovations. We are proud to have been one of the few companies on the market since the beginning of blow molding. Thus, we have made a big contribution to the fact that blow molding is so widespread and technically at a high level today. Today, we produce successfully at our site in beautiful Schwäbisch Gmünd.

"Low-manpower 24/7 blow molding production for our customers"

This is our guiding star, which we are approaching at high speed and in many innovative steps. From many conversations with our customers and experts in blow molding technology, we have derived our vision for the future.

Customers benefit in several ways:

- Plastics processing is continuous; Heating and cleaning processes are limited

- The output is increased enormously, which greatly reduces costs

- By significantly increasing the machine running time, investments to increase capacity can be avoided.

The focus of our innovations is on an integrated production system consisting of the elements of reliable machine technology + automation + digitalization.

In the design and development of this integrated new HESTA production system, it is crucial for our customers that they continue to rely on the proven new HESTA unique selling points of efficiency (highest OEE, material and energy efficiency, highest output rate, process tainability and much more), flexibility (fast changeover thanks to new HESTA quick coupler systems, Flexline and much more) and the unique compactness in the usual way. In this way, we provide our customers with essential competitive advantages in order to meet the constant demands of the market.

Today's challenges faced by our customers with the unavailability of qualified specialist personnel and operating personnel in shifts reinforces the need to find suitable solutions and support measures in a very timely manner. This, too, is a central aspect in the design of our system solution – assistance systems and digital tools will be the main support systems here.

HESTA presented

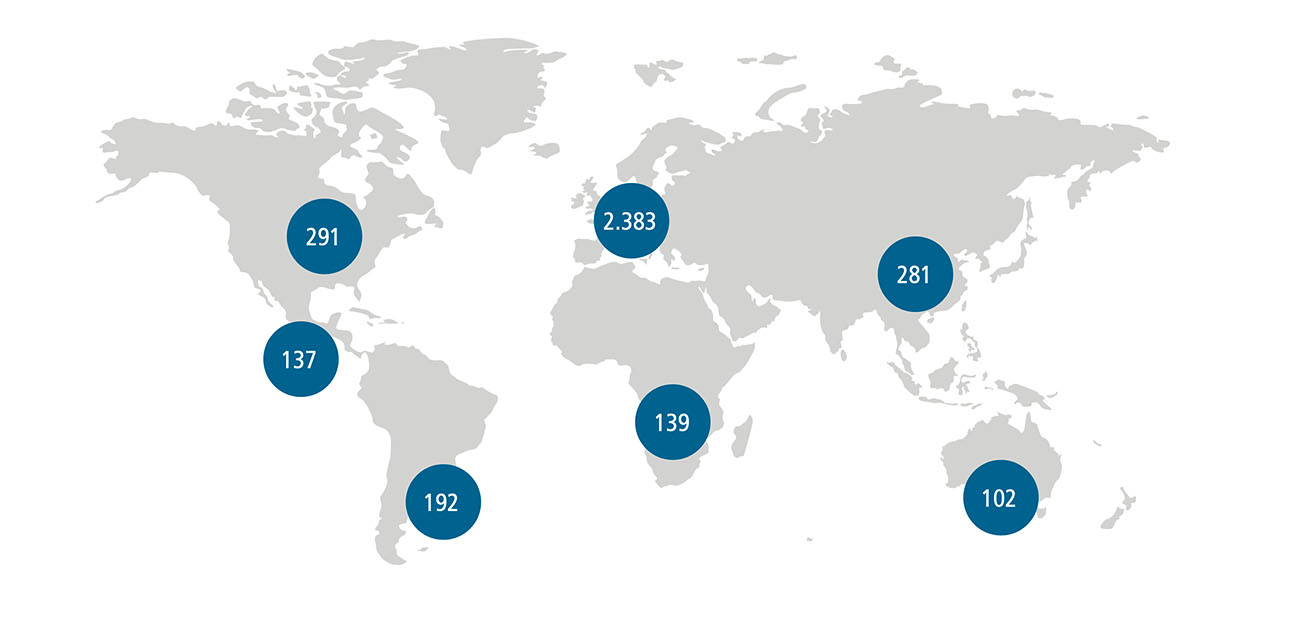

In use all over the world

Successfully certified

Quality

at new HESTA

at new HESTA

New HESTA attaches particular importance to high quality and safety standards in the development of its machines, automation systems and products.

This is also reflected in our quality management. We have successfully passed the DIN EN ISO 9001:2015 audit for the development, manufacture, distribution and service of extrusion blow molding machines as well as peripheral and automation systems for plastics processing.

The core of this certification is the orientation towards customer requirements and quality management focused on the individual work processes. Customer satisfaction is our top priority and that's why we work every day to improve and develop even better customer solutions.

If you have any further questions about our quality management system, please feel free to contact us at any time.

Voice Of The Customer

From small hidden champions to multinationals – we offer suitable solutions for all our customers.

We respond individually to your needs and deliver an optimal solution for you and your end customers.