Blow Molding Machines

Energy Efficiency & Sustainable

Our machine portfolio

Maximize availability.

Increase output.

Reduce production costs.

Guarantee service competence.

Maximize availability.

Increase output.

Reduce production costs.

Guarantee service competence.

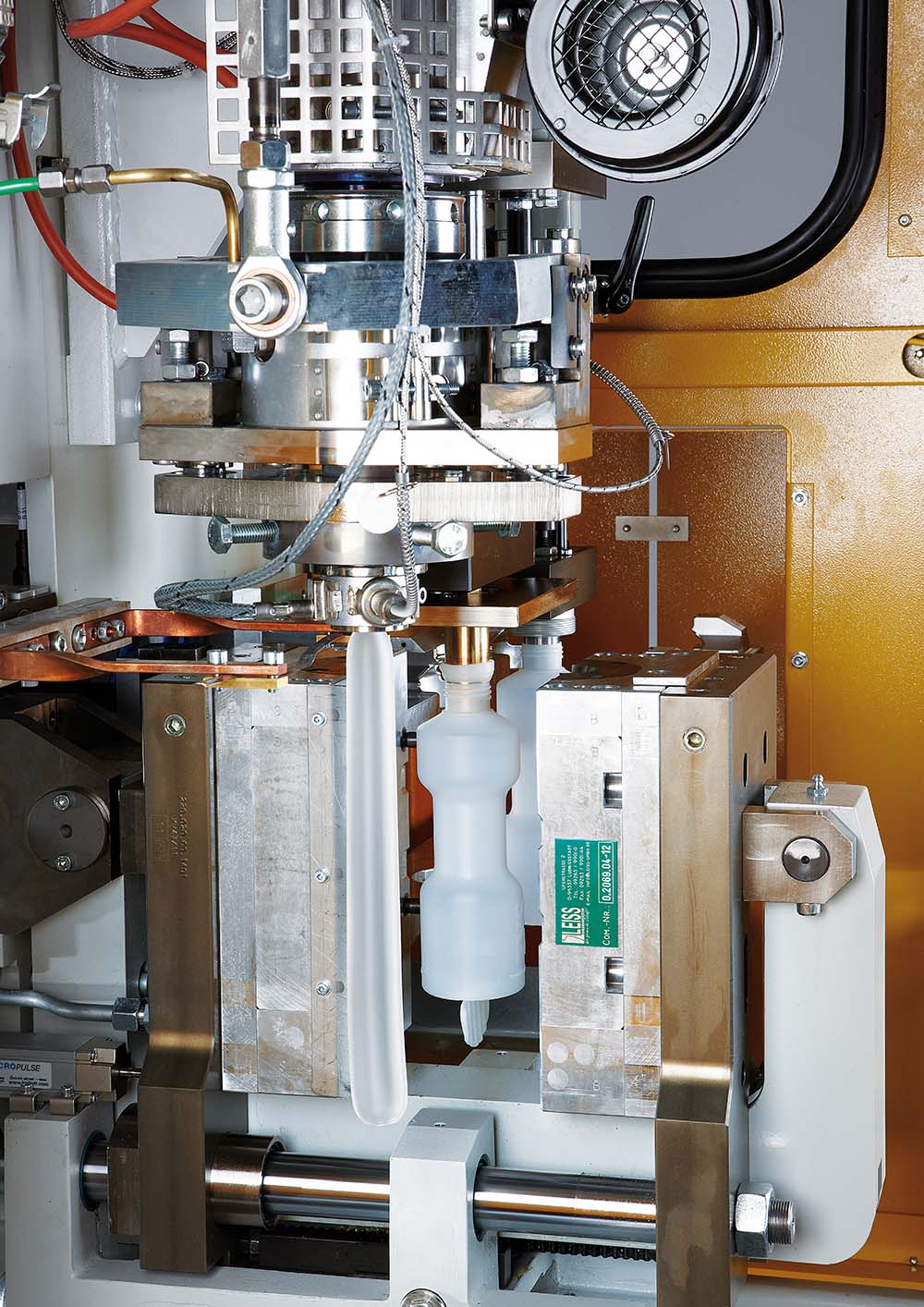

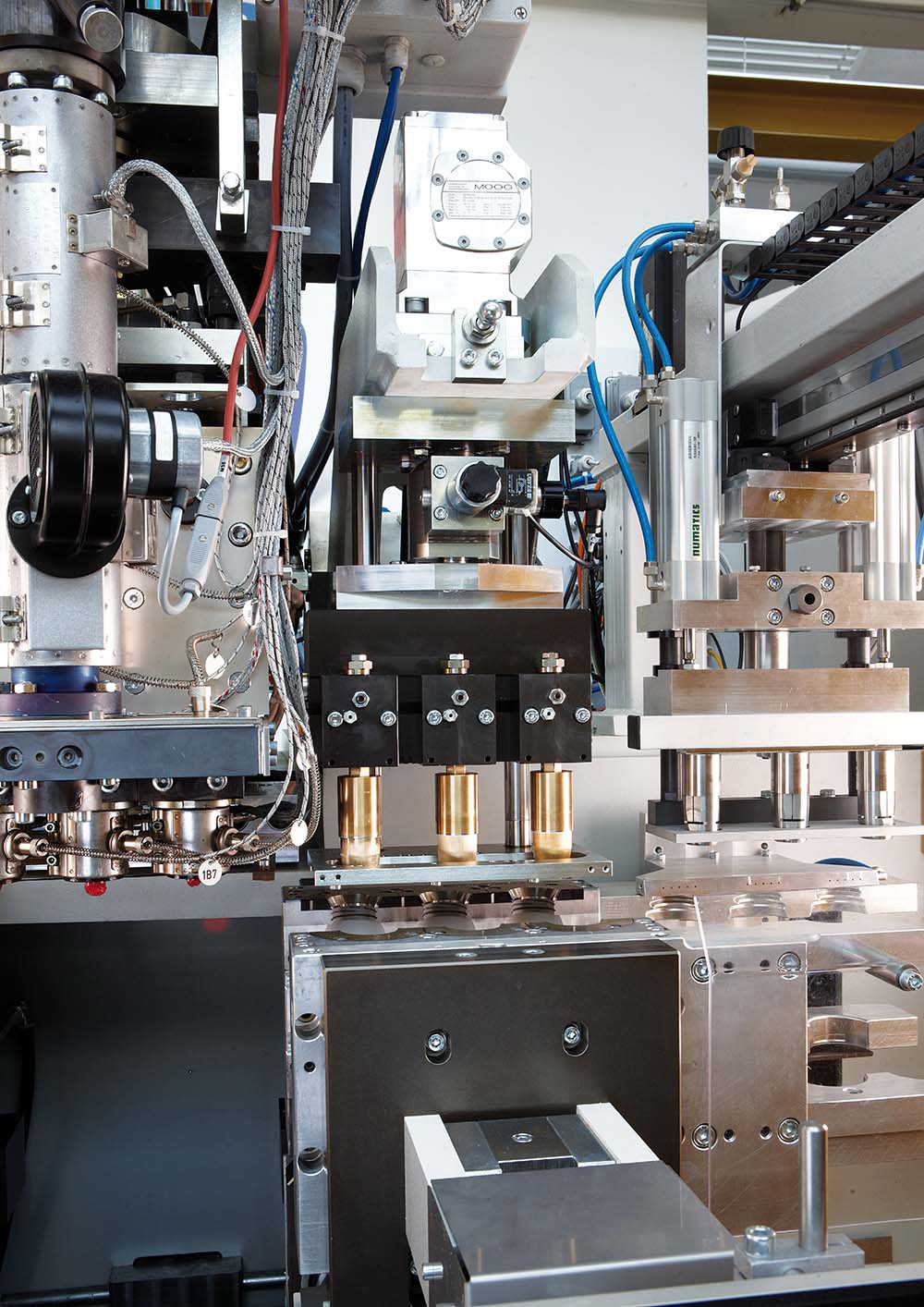

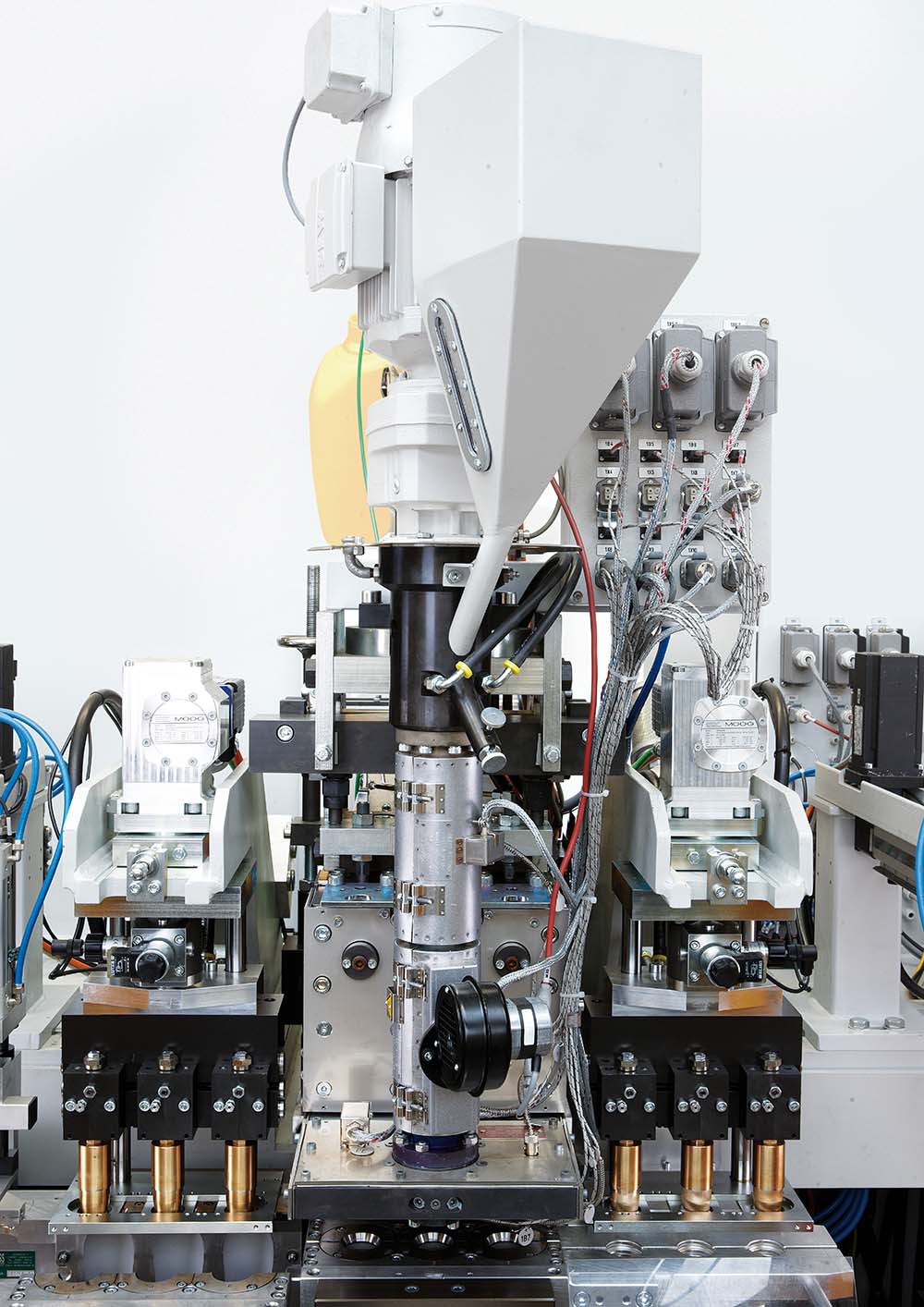

A robust, reliable machine design and the precision of the individual components guarantee high availability. Our team of experts has the experience of more than 3,500 HESTA extrusion blow molders installed worldwide.

HESTA uses state-of-the-art drive and motor concepts. Many components, such as the clamping and calibration unit, are patented. Our digital assistance system "IQ-Blow / Service and Diagnosis" offers continuous process monitoring during operation through monitoring. Any fault diagnoses are displayed with instructions for action. In the sense of predictive maintenance, indications of possible maintenance work are given.

HESTA blow molding machines save energy. The combination of state-of-the-art drive and motor concepts gives Hesta a unique position in the field of energy efficiency. Compared to hydraulic machines, our electric machines have up to 50% higher energy savings.

For our customers

Machine Insights

Get in touch

Do you have any questions?

new HESTA blow moulding solutions GmbH & Co. KG

Address

Werrenwiesenstraße 89

D-73525 Schwäbisch Gmünd

info@hesta.de

support@hesta.de

Daniel Knabel

Managing Director, Technical Director, Key Account

Phone +49 (0) 71 71 / 99 790 – 10

knabel[at]hesta.de