Solutions

Food & Beverage

In the food sector, hygiene is the most important quality criterion. For this purpose, our all-electric machines meet the very highest hygiene standards and support you with the best quality.

Whether it's neck-to-neck, bottom-to-bottom or just multi-cavity double-station machines for maximum production volumes, we guarantee to produce food packaging in all variants. Automation concepts enable our customers to drive unmanned vehicles with maximum efficiency. Minimal wall thickness with our tried-and-tested hose heads make a major contribution to material savings. Multi-layer applications and barrier layers guarantee a long shelf life for your product. For sensitive products such as juices or milk, the aseptic blowing device from new HESTA is part of the industry standard.

Consumer Packaging

The consumer packaging sector is characterized by an enormously large variety of blow molded articles on the market. The high degree of flexibility and the modular system of new HESTA ensure that we can cover them with the optimal customer solution.

Three main areas of this industry have evolved over time and formed their very own requirements:

- In the design-oriented cosmetics sector, the highest priority is placed on appearance and haptics. High-quality flacons made of PET-G and, if desired, with a thick base, create the unmistakable glass effect. For decades, we have been the standard in this field of production. Soft-Touch provides an incomparable feel or DeCo2 (2 layers) is used for the optical refinement of the blow molded articles.

- In large-scale production in the field of personal care products (shower gel, shampoo), the focus is on cost efficiency despite high quality requirements. Minimal wall thicknesses with our tried-and-tested hose heads make a major contribution to material savings and thus to competitiveness. Automation concepts enable our customers to run low-manned shifts with maximum efficiency.

- Containers for chemicals, such as household cleaners, are manufactured with our multi-layer heads and offer comprehensive protection against toxic and chemical products. They prevent diffusion and increase durability.

Industrial Packaging

Here, too, new HESTA is at home, in the sense of what the others can do, we have been able to do for a long time and, above all, better! With our new HESTA quick-change system, our customers achieve the shortest set-up times. In the case of high quantities and few set-up processes, we offer automation concepts in order to run shifts with few men with maximum efficiency.

Our unique Vario head technology enables our customers to produce visual strips, e.g. for oil bottles and oil canisters. In this area, there is also the possibility to carry out a quick and cost-effective conversion of your mono head to a viewing strip head with the existing Vario head.

Thanks to our patented new HESTA – HES (Stroke Adjustment System) and the reproducible closing force at every closing process, handle bottles and handle canisters can be produced in the highest quality

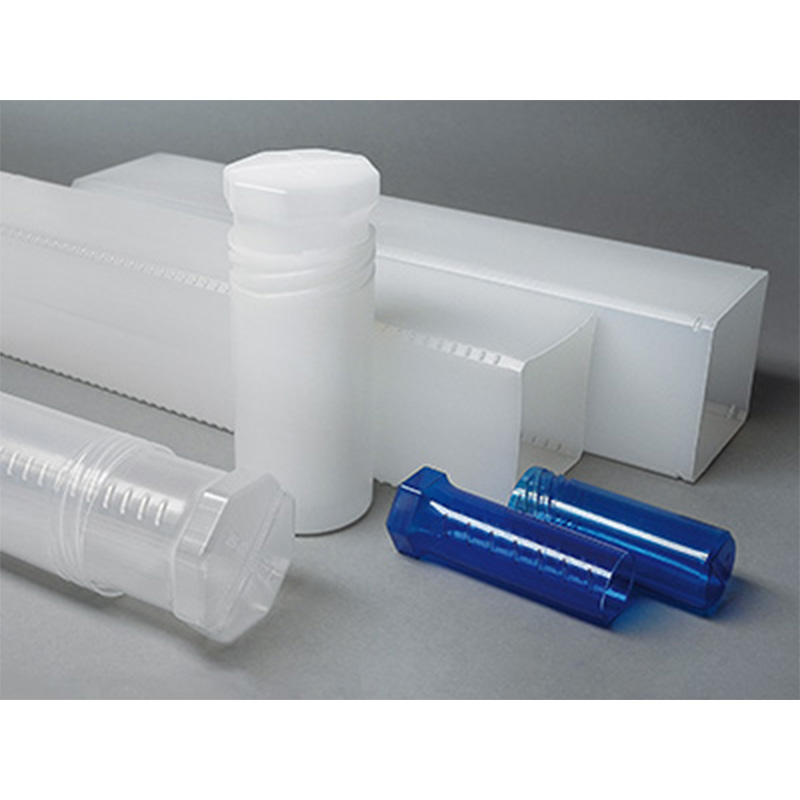

Pharmaceuticals

Whether you place the new HESTA machine in a clean room or create a cleanroom only in the production area of the machine, you can fall back on our many years of know-how for both variants.

The highest quality requirements of the pharmaceutical industry, such as leakage testing, various camera applications for 100% control of black spots, are indispensable and can be individually integrated into your customer solution. Product data acquisition and documentation meet the standard of GMP requirements in extrusion blow molding.

Technical Parts

The area of automotive parts and technical parts includes a wide variety of different products. From classic car parts, white goods, bellows, bowling pins, furniture, ice packs, to huge kayaks or small bobby car and wheelbarrow wheels – we can serve this high variance with our modular system.

We also have all-electric storage head machines in our portfolio for this industry, the control of various form sliders (electric, pneumatic, hydraulic), the integration of a PWDS (partial wall thickness control) or the control of robot handling systems are child's play thanks to our open and at the same time excellent control system. The possibilities here are almost limitless. Everything that can be blown can be produced with new HESTA according to our modular machine portfolio.

Our all-electric storage head machine not only impresses with the well-known small footprint of all new HESTA systems, but also sets standards in energy consumption. Thanks to our patented clamping unit with toggle lever, no energy is required for the guard locking during the complete blowing/cooling process. Whether needle blowing, 3D suction bales, 2-component (hard-soft combinations), we implement your production reliably.

Automotive Parts

The area of automotive parts and technical parts includes a wide variety of different products. From classic car parts, white goods, bellows, bowling pins, furniture, ice packs, to huge kayaks or small bobby car and wheelbarrow wheels – we can serve this high variance with our modular system.

We also have all-electric storage head machines in our portfolio for this industry, the control of various form sliders (electric, pneumatic, hydraulic), the integration of a PWDS (partial wall thickness control) or the control of robot handling systems are child's play thanks to our open and at the same time excellent control system. The possibilities here are almost limitless. Everything that can be blown can be produced with new HESTA according to our modular machine portfolio.

Our all-electric storage head machine not only impresses with the well-known small footprint of all new HESTA systems, but also sets standards in energy consumption. Thanks to our patented clamping unit with toggle lever, no energy is required for the guard locking during the complete blowing/cooling process. Whether needle blowing, 3D suction bales, 2-component (hard-soft combinations), we implement your production reliably.

Energy-efficient and sustainable

Our Blow Molding Machines

Voice Of The Customer