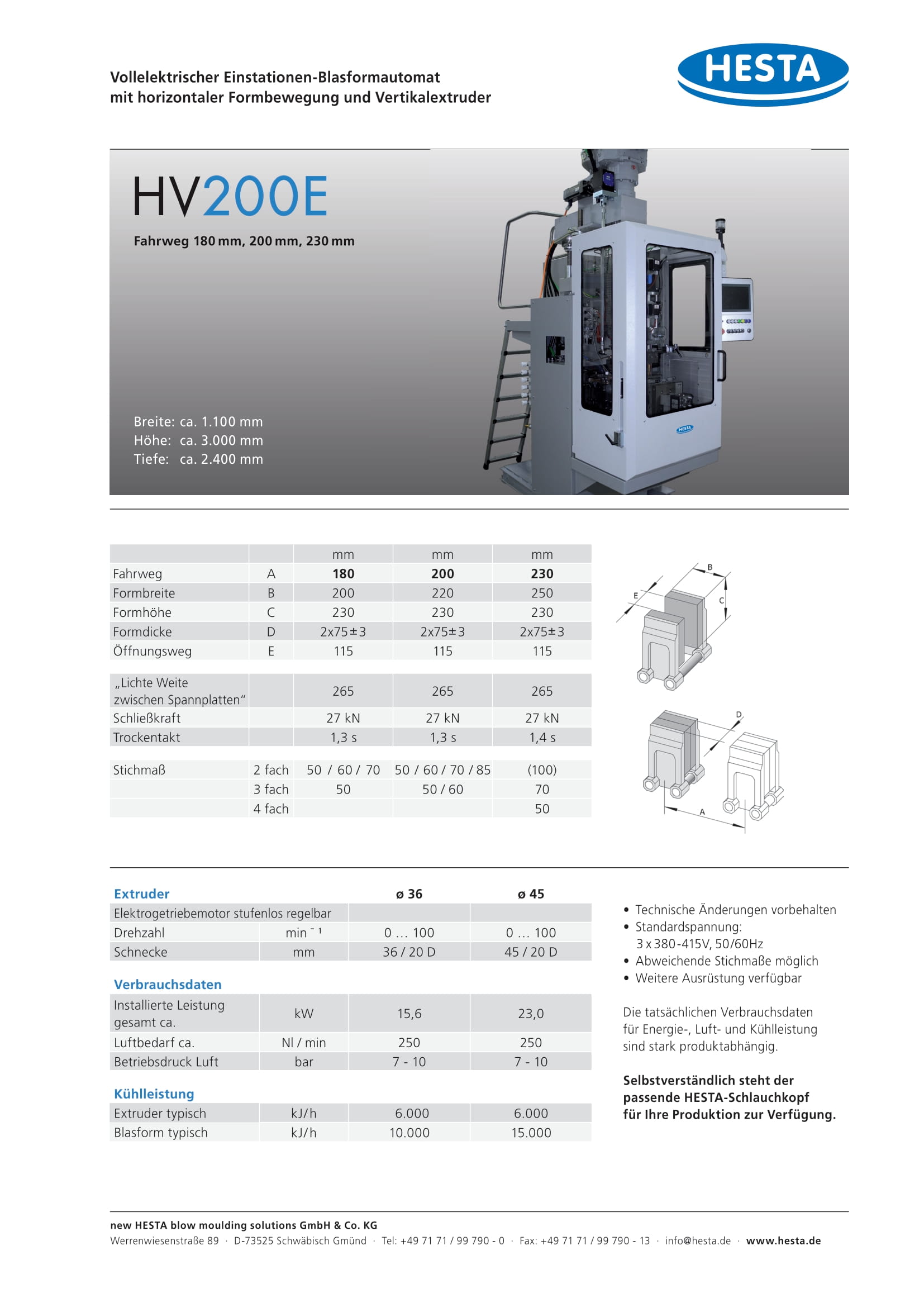

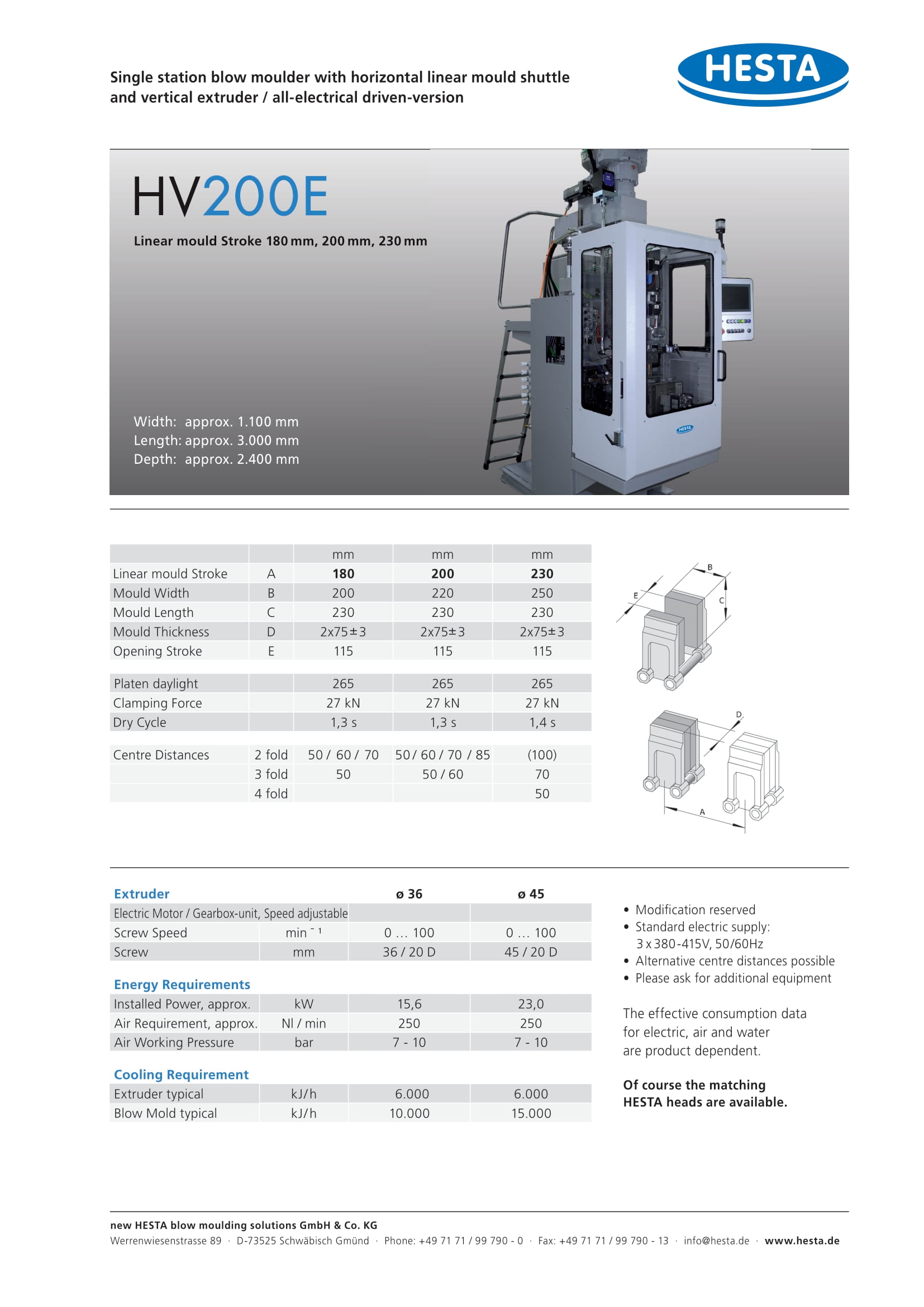

HV200E

Detailed description

The HV series of new RESTA blow molding machines are designed for small hollow bodies as well as for small batch sizes. Short changeover times result from the quick-change system for blow molding, from the simple replacement of screw and hose head. Due to their small space requirement, it is possible to set up several machines side by side, whereby new material feeding and hollow body and waste removal can be automated and easily solved at low cost.

Economic characteristics:

- High production output

- Precise and reliable operation

- Low acquisition and operating costs

- Low investment in blow molding

- Usage: HS moulds, HS hose heads, HS screws

- Easy operation and maintenance

- Quick change of blow molds

- Clean separation and safe removal of waste

- Material savings through the use of wall thickness regulation

- Small and large series production through expansion to production lines

- Easy processing of all thermoplastics, including PVC, powder or granules

- Long service life thanks to the use of proven components and high-quality materials

Technical features:

- Compact and service-friendly machine design, narrow front for installation in production lines, small space requirement only about 2 square meters

- Vertical extruder with longitudinal tube head Processing of thermally sensitive plastics much easier than deflection or angle heads

- Sophisticated machine design in which many years of experience are combined

- Electric-crank drives for the complete machine provides:

- for the mould closing system, fast movements, high closing force and finely adjustable closing delay;

- during the blowing process, an exact shaping of the calibrated bottle necks and high calibration force;

- High cost-effectiveness and operational reliability

- The unique extruder drive is not only energy-saving, but is also driven by four individual motors. This makes it easy to replace a single engine, as well as emergency operation or operation with reduced power while repairing a single engine.

- Control cabinet with clear design, and easy access to all parts

- Easy access to mold closure system, hose head and calibration device shortens changeover times

- The shortest distances between the extruder and the blowing station and during mold closing result in minimum dead times and maximum cycle rates

- A photocell monitors the length of the tube and enters deviations into the wall thickness regulation. The photocell can also be used without wall thickness regulation, especially with very long and heavy preforms, and results in exact tube lengths in a fully automatic work cycle.

The vertical extruder:

The vertical extruder with longitudinal injection head provides optimal material flow without deflection, excellent accessibility and minimal space requirements. The extruder can be easily adjusted in all 3 planes and allows reliable material feeding of all blowable thermoplastics from the hopper to the extruder through a connecting tube at a steep angle. The raw material, in powder or granular form with or without regenerated admixture, is safely fed into the extruder. This results in a uniform material feed of the screw, screw-on mixing or shearing parts for screws to optimize homogeneity and dispersion of certain thermoplastics round off the portfolio. Optionally, 20D extruders with a diameter of 36 or 45 mm can be used. A photocell is used to determine the length of the tube. For PE processing, a screw with a mixing part is used. In PVC processing, screws with internal cooling and cooling fans are used on the extruder. The unique extruder drive is not only energy-saving, but is also driven by four individual motors. This makes it easy to replace a single engine, as well as emergency operation or operation with reduced power while repairing a single engine.

Hose heads:

The hose heads are equipped with double-web mandrel holders for the processing of thermally sensitive materials (PVC) or highly transparent materials (PETG) and with offset mandrel holders for polyolefins that are suitable for flow technology. Single, double, triple and quadruple hose heads are available, also with nozzle adjustment device. Vario hose heads for visible strips or DeCo2 round off the concept.

Tubular knife:

Cold and hot cutting systems are available to cut the hose, these are pneumatically driven, but can also be extended with our unique Electric High-Speed Knife. With a speed of up to 12 m/s, this knife cuts the hose before it notices anything. Thus, the folding of the hose is reduced to a minimum. The portfolio is rounded off by our hose sealing and disconnection device with controlled support air.

Blow heads:

Calibration is done electrically with a maintenance-free crank drive with 13kN calibration force. The universal blowing head is safely guided on both sides; The patented calibration pad ensures easy 0-point calibration of the mandrel height to the tee edge in the mold, and reproducible set calibration force for each cycle. The blowing mandrel height adjustment, the centering of the blowing mandrels to the mold opening, is very easy to do. The blowing mandrels can be water-cooled up to the tip. It is also possible to provide oblique calibration.

The locking system:

The open C-frame closing system with two lower bars has an infinitely adjustable closing force of up to 27 kN and is also driven by a maintenance-free crank drive, as well as adjustable mold opening travel. The spars are not subject to bending stress and therefore cause the clamping plates to be guided exactly, and the cooling water is returned by the bars themselves. The patented closing cushion allows you to calibrate the mould thickness of +- 5 mm fully automatically, the closing force can also be optimally adjusted to your article in set-up mode. Human misalignment is excluded with new HESTA. If the machine detects a slight deviation during production, it immediately performs an automatic set-up and adjusts the clamping force. The blowing tool is freely accessible. The lightweight construction results in low masses and thus short cycle times. Two separate cooling circuits are available in each strike plate, whereby the integrated cooling circuit connection through the strike plates not only makes a major contribution to quick change, but also fails connections are excluded.

Directional transport:

The blown articles are removed from the blowing mandrel by masks mounted directly on the blow mould and transferred to the next station in one level, so alignment and set-up is no longer necessary and saves extremely set-up time. Double masks can be used to operate an additional follow-up station (e.g. for leak testing). As a result of the transport, the hollow bodies are cooled down well and the output rates are increased. Neck and bottom slugs, as well as handle waste, are removed by pneumatic punching cylinders.

E-drives and pneumatics:

Energy-saving servo drives supply the extrusion unit, the shifting and closing movement as well as the calibration. The associated servo drives from Beckhoff are always of the latest generation and enable cost-effective production by optimally adapting the energy consumption to the utilization of the machine. The pneumatics control the functions of blowing, cooling and transporting. Punching and ejection with proven, mature elements. The standard pneumatic valves are arranged on a central base plate for easy servicing.

Control cabinet & control:

The electrical control cabinet is vibration-damped, easily accessible and easy to service mounted on the machine. The programmable logic controller with front panel meets the highest standards of reproducibility, simple, safe and clear. It allows individual input of all setpoints for the motion sequence, heating and wall thickness regulation as well as the integrated bottle tester. An internal background memory facilitates setpoint optimization. All inputs and fault messages are displayed in plain text. The warning and monitoring systems, which are part of the basic equipment, control the entire machine process. In the basic version, four authorization levels secure unauthorized entries, and personalized login can also be activated as an option. Inputs and all fault messages are recorded for the purpose of tracking processes. For ease of use, two monitor sizes are available, depending on the type of machine. The coloured 12 and 21 inch touch panels are directly connected to the Windows-based modular control system. Any number of setpoint sets can be stored on an internal memory or conveniently via a USB socket on an external memory. This shortens changeover times, especially for small batch sizes, and increases cost-effectiveness. All common languages can be switched quickly and easily. Preparation for online service is a matter of course and easy for us by means of a pre-installed software.

Accessories:

Additional devices complete the HV program:

- The electronic wall thickness adjustment with maintenance-free crank drive allows the wall thickness to be pre-programmed over the entire length of the hose with 100 points, whereby the timing automatically adapts to the cycle time of the blow molding machine.

- The fully automatic production of wide-mouth containers is carried out by circular cutters with either electrically or pneumatically operated, circulating knife for the removal of the lost head outside the mould in the trimming station, whereby horizontal or vertical cutting is possible.

- The fully integrated bottle tester is used for leak testing and neck checking. This can optionally be extended by a neck passage test. This means that bad items are not handed over in the first place and fall directly onto the slug waste belt. Since 100% tested bottles are transported out of the machine, complaints about leaking bottles are a matter of embarrassment to the end customer.

Get in touch

Do you have any questions?

new HESTA blow moulding solutions GmbH & Co. KG

Address

Werrenwiesenstraße 89

D-73525 Schwäbisch Gmünd

info@hesta.de

support@hesta.de

Telephone & Fax

Phone +49 (0) 71 71 / 99 790 – 0

Fax +49 (0) 71 71 / 99 790 – 13

Daniel Knabel

Managing Director, Technical Director, Key Account

Phone +49 (0) 71 71 / 99 790 – 10

knabel[at]hesta.de